For all the innovation in the world, construction is conspicuously lagging behind. On this, Jan Houtekamer (director cepezedbouwteam) and Willem Neeleman (director Tardis Innovations) heartily agree. Still, there was plenty to talk about. After all, how do you change this?

Jan: ‘You are a product developer who switched from the automotive industry to the construction world. We find that interesting at cepezed, because we also see architecture as a product.'

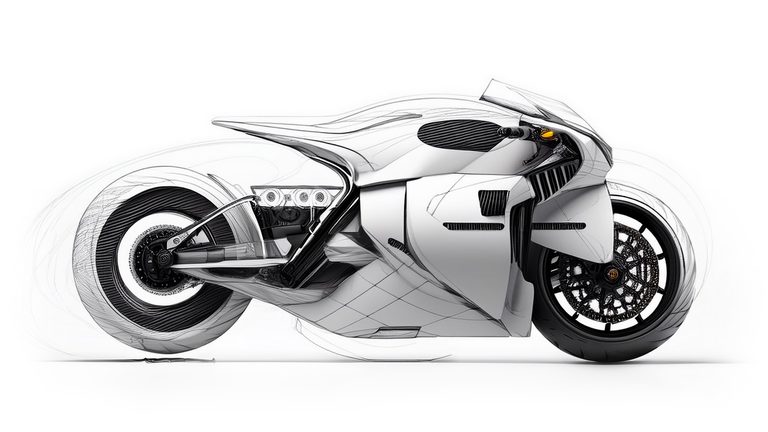

Willem: ‘Yes, I worked in the automotive industry for 17 years, at dealerships and importers. In the beginning, I was involved in the after-sales of motorbikes. I noticed even there that it gets syrupy where one department stops and another starts, even if you work on one product. It is important to properly name that boundary. Later, through two other companies, I got a great insight into manufacturers in terms of product development and production developments. Through ActiveWarmth, where I worked on conductive polymers and wall heating systems, I ended up in the construction industry.'

Jan: ‘So it started with a particular material?’

Willem: ‘Yes, with the aim of CO2 reduction. I noticed that there was little use of knowledge like this in construction, perhaps because construction is traditionally a craftsmanship-driven craft. Architects and clients always want something new, they make a one-off. Compared to the car industry at least, where each brand clearly has a defined and recognisable identity, and as a customer you choose an existing type that fits your image.'

Jan: ‘Mm, does this comparison really hold true?’

Willem: ‘The car industry doesn't work with a specific set of requirements that is then captured by an architect in a unique design.’

Jan: ‘But in housing construction, surely much is the same, the difference there is at most in the finishing package. I feel that the ‘one-off’ lies in the ever-changing composition of the team.'

Willem: ‘The construction industry makes little use of learning ability, is my experience. The automotive industry is more future-oriented, there it's all about learning, implementing, evaluating and learning again. In construction, the house, i.e. the product, is standardised instead of the process. In the recircular houses I realise with my company in Nijmegen, of which 99 per cent of the components can be reused, we have standardised the process. As a result, the nave dimensions, for example, can differ from one house to another. We redefine the interface, both of components and of batches.'

Jan: ‘How do you do that?’

Willem: ‘Basically by standardising the construction method. The same industrialised platform as in the automotive industry ensures that the connections between components are standardised - whether such a platform is used for a Golf, Skoda or Audi, the assembly is identical. Standardising building nodes and interfaces ensures quick assembly and disassembly, as well as fused performance of connections. When assembling the home on site, we work with assembly specialists, people who are trained and know what actions need to be added. It is an unambiguous and simple way of assembly, we also use colour-coded tie-wraps, for example. As a result, no holes are just drilled anywhere.'

industrial built or a one-off?

Jan: ‘Does it make a difference that construction always takes place on location, while you make a car or motorbike in the factory?’

Willem: ‘Not necessarily, but if you don't have the logistics in order then you get the very problems you wanted to avoid. In Nijmegen, we showed that the structural phase can be combined with the finishing phase. A team assembled the shell including the complete inner walls in one day. The team working on the structural phase is jointly responsible for the finishing phase, which also prevents mistakes. We are now looking at how to optimise the construction process across the chain. Which boils down, in short, to designing the interfaces in such a way that everyone applies them with the same result.'

Jan: ‘Interesting that you guys are thinking about this.Technical as they are, designers often assume this will be understood.You think more from the action than from the result.'

Willem: ‘I see the building code as the minimum and consider every home as my own.I am also committed to CO2 reduction and no longer want to use polyurethane foam. And not the cost, but the future relevance of an element is leading.'Jan: ‘And that with as little material as possible...’

Willem: ‘Indeed, that has mainly been the quest; we were able to make the houses in Nijmegen some 20 thousand kilos lighter than traditional prefabricated construction.’

Jan: ‘The construction world has answered the problem of quality versus quantity with the “building factory”.How do you view that phenomenon? Is construction getting smart here?'Willem: ‘I find that difficult to judge, the size of the factory then determines the degree of innovation at component level. We have a business model à la General Electric, where we align suppliers within the industrialised platform and increase sustainability ambitions one on one.'

Jan: ‘With the architect as director, you mean?’Willem: ‘For me, the role of the architect is in the corner of look and feel, aesthetics and spatiality.’

Jan: ‘Isn't that a bit limited?’

Willem: ‘I don't think so.In the car industry, for example, thick books have been written with treatises on the driver's seat.All brands know how to turn the regulatory challenge into a recognisable brand uniqueness.This is what I mean by standardising construction methods.'Jan: ‘Who do you see as the director of the interfaces of all components?’Willem: ‘We are now organising that ourselves as the designer of an industrialised platform.By basing that on clear design criteria, we make different choices.'

Jan: ‘I am a fan of the architect as director of the entire building process.Because the architect knows better than anyone else how the whole thing fits together and can therefore best monitor that whole.'

Willem: ‘You have to avoid unexpectedly inventing new things and creating that one-off situation.The industrialised platform gives an architect a lot of freedom to customise the house. The role of monitoring this standard does not lie with the architect.'

Jan: ‘But who else but the architect can do this?’

Willem: ‘All roles in construction are changing. I think it's a matter of redefining the role of the contractor.'

Jan: ‘Yes, the contractor used to be like the car manufacturer, today the dividing line lies with the supplier. We need to take ownership of the interfaces again. It is now the case that the Quality Assurance Act can even work against you.'

Willem: ‘In Nijmegen, we worked as the main contractor and with Bouwq and Allianz, we delivered the houses with insurance for hidden defects. My role was to innovate the interfaces for the industrialised platform and strengthen the unified way of working.'

Jan: ‘When you innovate, it helps to clearly define your own role.Not risks, but solutions and opportunities should be leading in contractual frameworks. In this respect, Van Wijnen's housing factory is interesting.Here, it works with one contract and one team for everything, so parties are not opposed to each other.The downside is that such a factory produces uniformity sausages. Like you, I see smarter organisation of the manufacturing process as the current construction task.'Willem: ‘It sometimes seems as if different disciplines happen to come together on construction sites. They do their own thing, with no idea of the end result.That fragmentation explains why the learning capacity is so small - you don't get feedback.In Nijmegen, that kind of knowledge was not lost. We showed that, using the knowledge of all parties, you can make an integral design that four assembly specialists and a machinist can very well erect a house, which can also be moved.'

Jan: ‘You made an assembly manual for that, right? On the building site, I think the question of how it was really meant to be done comes up too little, even if, as at cepezed, new ideas have been developed.'Willem: ‘Very different from the automotive industry, where you keep monitoring and repairing products or taking responsibility with recalls. Construction is an idiotically overstrained market, therefore the emphasis is on other things than a manual. Our assembly and disassembly manual ensures quality as well as speed.It contains every step of the assembly process, including the manpower required, right up to the final result.Moreover, we use clear criteria for the recircular home, which are measured against the sustainability ambitions.Because of that clarity, there is no deviation from those criteria.'Jan: ‘Do you envisage a development in which the designer and the contractor become one?’Willem: ‘In Roman times, the architect stood at the opening under the aqueduct he had designed.That love for the profession is nice. But I still think the contractor will keep a central role.'

Jan Houtekamer is director of cepezedbouwteam

Willem Neeleman is product developer and director of Tardis Innovations

→ return to overview

→ Mail bd@cepezed.nl or call our business development team on +31 (0)15 2150000