ingenious design

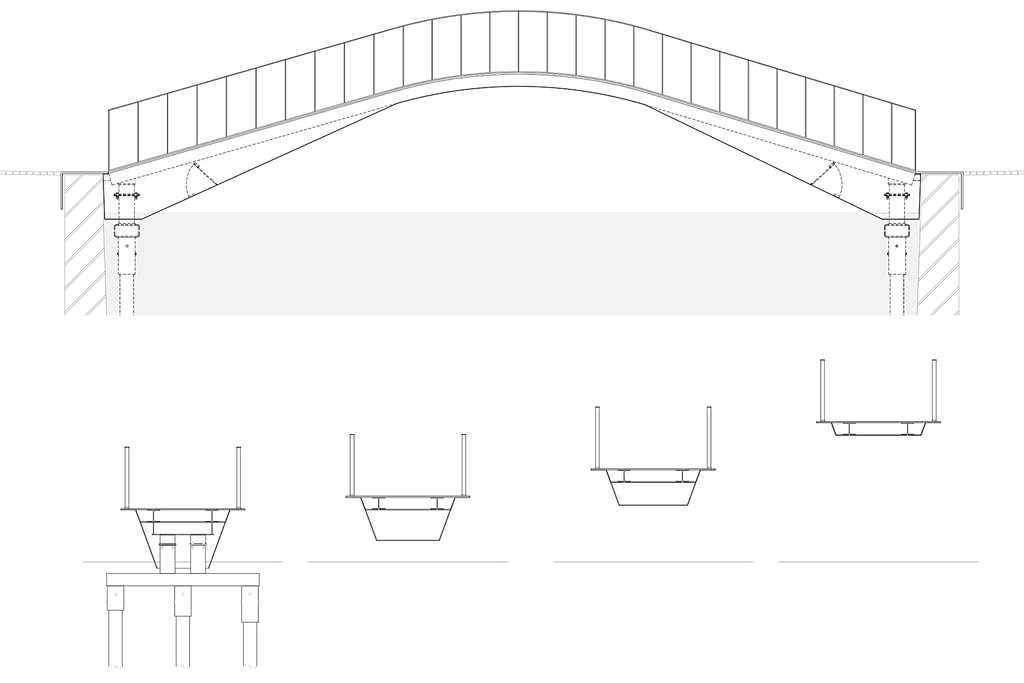

The bridge sections were prefabricated and lifted into place from a pontoon, with four inches of clearance on either side. To protect the monumental quays, the bridges rest on a submerged construction. This submerged structure is an ingenious, stepped system of screwed-in piles. By allowing two tubular piles to rest on three tubular piles, with a steel cotter in between, the width of the bridge deck remained small. The pile sections were welded on site, screwed into the bottom of the canal, and filled with grout.

The bridges connect directly to the quays, so raised landings or other modifications to the monumental quays were unnecessary. A steel runner serves as a barrier-free transition and covers the small rift between the bridge and the quays. This gap formed due to the combination of the tapered quay and the bridge which – in view of the structural forces – is straight. The gap contributes to the idea of a 'floating' bridge created by the hidden foundations piles.

The construction is kept out of sight as much as possible, partly by bolting from below. The balustrade is attached to the bridge deck from the underside. For maintenance and inspection, two hatches were made in the underside of the bridges. The chosen construction method not only keeps the bridges slim, but also makes them demountable.